Lean tools and Covid 19 (English)

Prof.dr Vojislav Stoiljković

Lean tools and Covid 19 (English)

From the end of March to the beginning of April this year, when the COVID 19 pandemic was widely discussed, many Lean experts have been trying to point out the possibilities of applying Lean principles and tools in the care and treatment of COVID 19[1][2][3][4][5]. , members of Lean Sensei (a teacher in Japanese) women, in their article say, among other things: “No matter who you are, what organization you work for, or at what level you are practicing Lean, we are all affected by COVID-19. And everyone in this world – our world – must do what they can to help. As Lean Sensei Women, we have put together some suggestions and ideas for your organization to use (and of course, you can apply many of them at home as well). They’re simple and easy, can be implemented quickly, and are all based on our lean principles of respect for humanity and continuous improvement.”[6] It is further stated in this article:

The first, and most important thing, is safety, both physical and psychological: Whether physical safety in manufacturing, or psychological safety in services, or both, keeping team members and customers safe is always our first priority in Lean. Here are some suggestions to try:

- Limit the number of people working and increase the distance between them (Arrange for people to work remotely; Provide point-of-use-cleaning supplies (Lean tool – Point of use); Teach people proper hand-washing techniques; Use PDCA to make changes in response to the new government and organizational regulations).

- Ensure the psychological safety of workers (Treat people with respect; Guard against overburden; Make a plan to help team members that become ill).

It is well known that the Covid-19 Pandemic pushes the healthcare system around the world to its limits and, despite the heroic efforts of healthcare workers, hard work is often not enough. Images coming from the hardest-hit areas tell us about emergency areas filled to the brim, hospitals struggling to treat everyone because of the very large number of people the virus sends to the ICU (Intensive Care Unit), and the exhausted staff who often forced to work without adequate protective equipment.[7] In the above article, which was published on April 3, 2020, experts on the Lean concept from (Instituto Lean Management, Barcelona, Lean Institute Brasil, Lean Enterprise Australia, Lean Enterprise Institute, Boston i Instituto Modelo de Cardiología Privado, Cordoba, Argentina), as the Global Lean Health Initiative, list seven key Lean practices – each with a set of effective tips – that can really help the health team address this case more effectively.

- Design the patient flow

- Visual Management

- Standard work to ensure safety, quality and efficiency

- Engage in short, structured communication cycles

- Build skills fast with a people-development plan

- Review priorities to ensure capacity

- Level capacity and protect staff

When it comes to designing the patient’s flow, it is necessary to understand the demand (patient influx) and pace for each patient flow, to physically separate the flows, to develop a plan for each patient flow, depending on the severity of symptoms (apply Lean tool Spaghetti diagram) and, perhaps most importantly, to encourage the application of the Lean principle of “pull” (for more on the application of the Lean principle of “pull” in the fight against COVID 19, see the author’s article cited in the references under 1).

For each of the tips, the authors give examples of successful implementation in their countries.

Application of Lean tools Visual management is of particular importance when it comes to separating the flow of patients with different levels of disease symptoms, in order to avoid overlapping patient paths. This means that visual signs should be clearly placed on each bed to reduce the time to obtain the necessary information. The goal is to create visual data that will provide the necessary information in a second. In doing so, different color codes should be used for areas, tracks, classifications, such as area purpose, so that they can be changed quickly and tracks can be extended or reduced overnight. In this way, everyone is in step with the development of the situation.[8]

In this article, the author will discuss in more detail the application of the Lean tool Spaghetti diagram in the process of care and nursing of patients with COVID 19. In the following, we will talk about other Lean tools that can be used to improve the process of care and treatment of COVID 19 patients.

In the context of Covid-19, “safe” has a lot to do with distance (for which the global standard is two meters) and exposure (how long it has been exposed to the virus). The media and governments do not use the term “stream” on the other hand. They should use the Lean flow principle. For each Lean activity, health thinkers first define value through the eyes of the patient and medical staff, and, in and of themselves, they all want to be safe. In a situation with a COVID 19 pandemic, this requires shortening the lead time (the time from symptom identification to the start of treatment and cure) to ensure that we are at potential risk of infection in the shortest possible time. For healthcare facilities moving under the new rules due to COVID 19, this means enabling flow to ensure that value-added activities can be performed one at a time (Lean principle one-piece flow), without interruption. This reduces the time required to cure a patient infected with COVID 19.

Spaghetti diagram

A spaghetti diagram is a visual representation that uses a continuous flow of a line to track the path of an item or activity/task through the process. Continuous line flow allows process improvement teams to identify redundancy in the workflow and opportunities to speed up the process flow. Spaghetti diagram reveals inefficient schedules, safety risks, and identifies long distances between key steps in the patient care process.

A spaghetti diagram is a diagram of a department or object that shows the path a patient takes as they go through the process. The spaghetti diagram can also show all the steps and paths that medical professionals follow to complete their work. All the beginnings and stops and great distances covered are sometimes a big surprise. Strive for the final spaghetti diagram to minimize beginnings and stops, waiting, and distances. It should show a continuous, direct, and efficient flow.

With the help of spaghetti diagrams, you can identify some of the sources of the problem and communicate where the risks to safety and waste are in the process. It also helps you decide on the next steps you can take. For example, you can use the spaghetti diagram to change the layout of the department to improve the efficiency of departmental flows.

The spaghetti diagram is a tool to help you establish the optimal layout for departments or hospital rooms based on observation of the distance traveled by patients, staff, or reports (e.g. ultrasound or X-ray reports). Spaghetti diagrams reveal inefficient schedules and identify long travel distances between key steps.

Spaghetti diagrams are a key contribution to the creation of standardized work that shows the movement of patients and medical staff and the position of the material in relation to the physical environment. It is probably the simplest and certainly one of the most visible visual techniques. It is used to create process steps by tracking the movement of people, information, or materials and drawing movement lines to visualize it. In order to understand how to get the job done as efficiently and efficiently as possible, we typically record the distance traveled, the number of steps and the time required, and any feedback processes to complete the process. We should also consider any security issues arising from insufficient optimal scheduling or steps in our process.

Examples of Spaghetti Diagrams

To draw a Spaghetti diagram, you first need to decide what to look at, e.g. equipment, medical staff, or patient flow. You can choose to analyze a large number of them simultaneously (equipment, medical staff, patients, visitors, outside associates, etc.) using different line colors that represent each flow. In testing laboratories, these may be different tests (eg urine, blood …).[9]

Draw the layout of the area (layout) and then draw lines on the diagram to represent the main flows of the staff or patient.

By analyzing the lines, you can identify all areas with unnecessary movement. This helps staff decide whether to approach two points on an existing path and optimize the flow.

Furthermore, real examples of recorded Spaghetti diagrams within the implementation of the Lean project 2012-2013 are presented. year at the Clinical Center Nis.

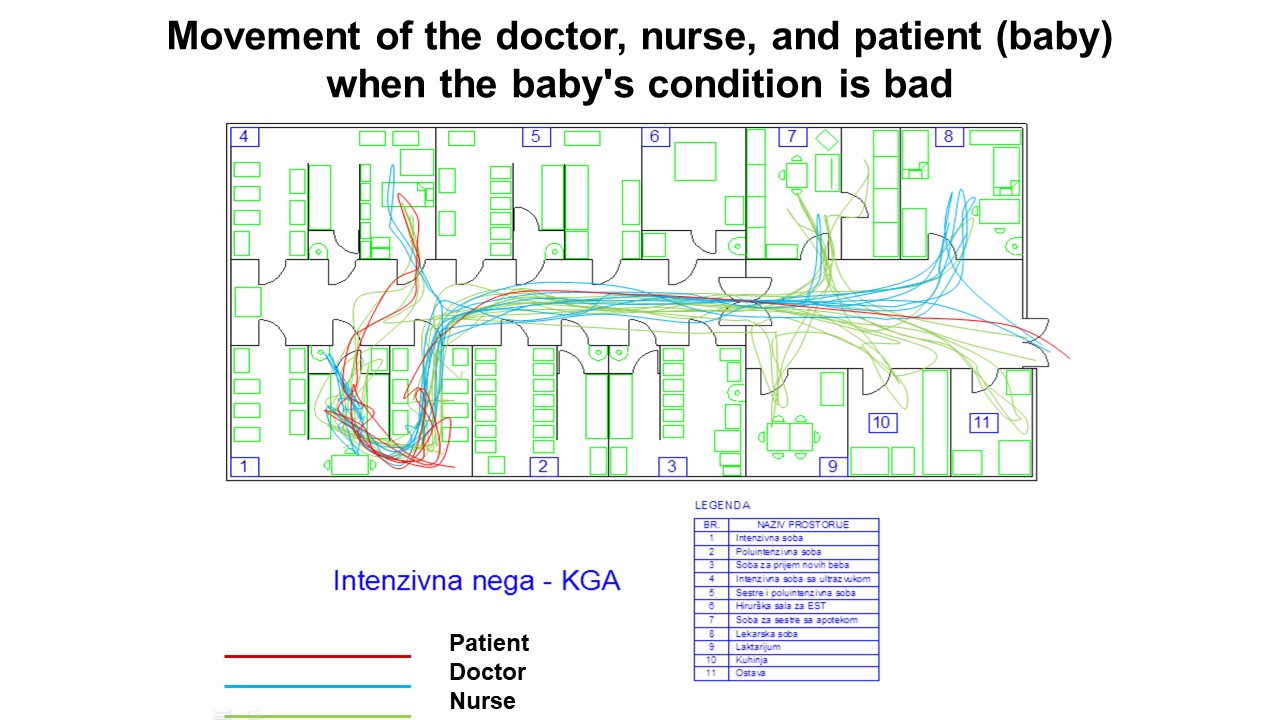

Since the layout of the premises is drawn, the person who should monitor the movement, in our case, of the newborn baby, the doctor, and the nurse, is in charge (it is also possible to follow the delivery routes of medicines, medical material, etc.). This is how the lines of movement that correspond to the state “as it is now” are obtained. For example, a newborn baby is transported for an ultrasound, or for some analysis, or sent to another clinic (KDIB or KDHO*). Thus, a spaghetti diagram was obtained that shows the movement of the baby, the doctor, and the nurse during the day.

*(KDIB – Clinic for Children’s Internal Medicine; KDHO – Clinic for Pediatric Surgery and Orthopedics, KGA – Clinic for Gynecology and Obstetrics; KCN – Clinical Center Nis)

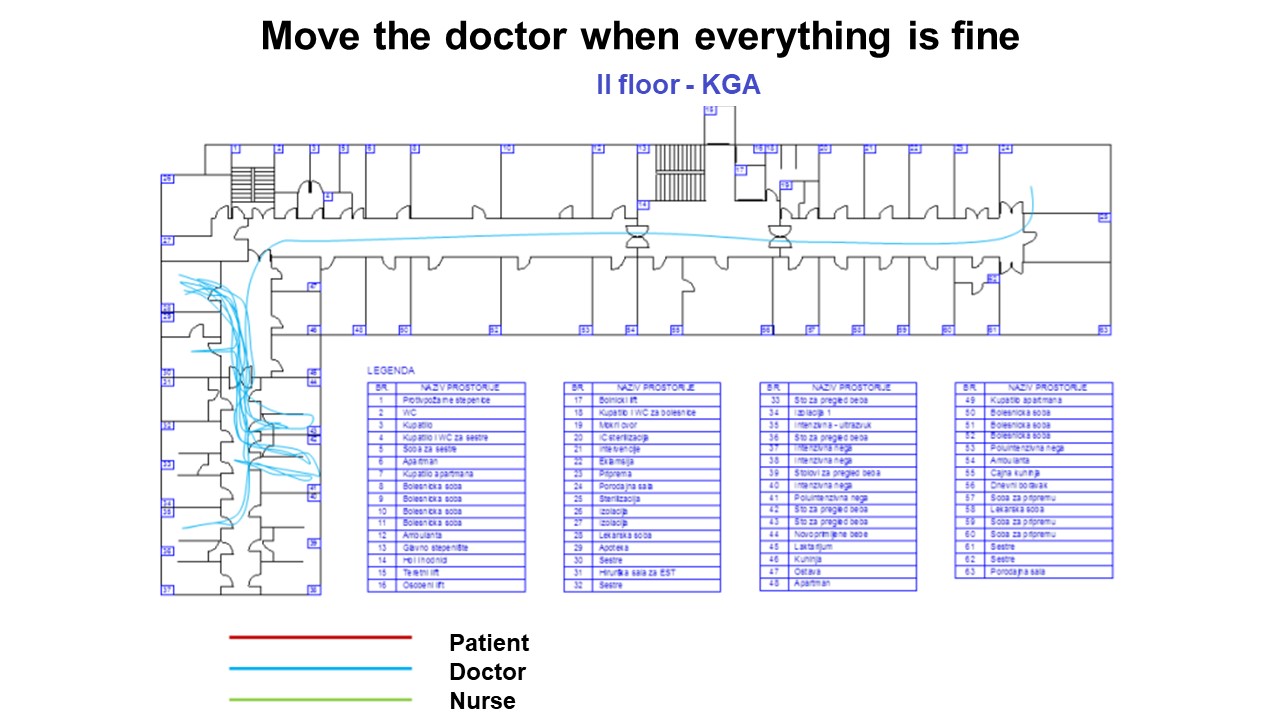

Figure 1 shows spaghetti diagrams taken in the intensive care unit at KGA KCN for the movement of the baby, the doctor’s nurse when everything is fine with the baby (patient).

Figure 1 Spaghetti diagrams on KGA Intensive Care when everything is fine with the baby

Figure 2 Spaghetti diagrams on KGA Intensive Care when the condition of the baby is bad

Recorded spaghetti diagrams (not only on KGA, but also on KDIB and KDHO, as well as in the Center for Medical Biochemistry) give improvement teams the opportunity to consider options for defining a new room layout, to reduce unnecessary movements and thus waste. One of the ideas that arose after recording the Spaghetti diagram at KDOH in intensive care was to move the auxiliary pharmacy, which is used daily for neonatal treatment, directly to the wall next to the incubator, i.e. to be stored at the place of use (Lean tool POUS was used). – Point of Use Storage). This avoids unnecessary walking by the nurse when giving therapy to the baby. Movement with each medication is reduced by approximately 20 m (movement to the pharmacy and back to the incubator). If it is known that during the day the nurse covered that distance up to 50 times (there are 4 incubators in the room), it means that the movement was reduced by about 1,000 m. More importantly, the nurse was able to react immediately when there is a need, not to go for the necessary drugs or medical supplies.

Designing and implementing Spaghetti diagrams in the treatment process of COVID 19 may initially be a headache for medical staff, but it won’t be long before you realize how strategically locating patients and pathways can increase safety, shorten the time required for certain activities in the process. Imagine how defining, through Spaghetti diagrams, in the movements of patients and medical staff will increase safety and facilitate the work of medical staff. This requires using the existing schedule at COVID 19 Hospital and hiring an expert who knows how to draw a Spaghetti diagram. Following the movements of patients and medical staff and in cooperation with medical staff, it is possible to define the optimal and safe flow of all participants in the process.

Visual management

Since the Spaghetti diagrams were recorded, it is necessary to apply Visual Management, i.e. to mark the paths of movement of patients (with less and more severe symptoms), doctors, nurses, and other medical staff.

Visual management is a powerful tool that uses visual techniques to communicate information widely. Think in terms of a new person entering the process area and understanding how the process is executed in less than 2 minutes, without any explanation? The benefits of applying visual management can be seen in almost all situations where it is better and cheaper to communicate directly to associates.

In Lean operation, all processes are clearly defined, documented and where possible, visually, or audibly controlled.

- Visual inspection

○ Displays the current status of the process

○ Signals need to take action

○ Strengthens standardization

- Often visual, but can be audible.

- Visual controls help make things work as efficiently as they are designed to work.

- Visually enhancing the process helps to align behavior with standard work.

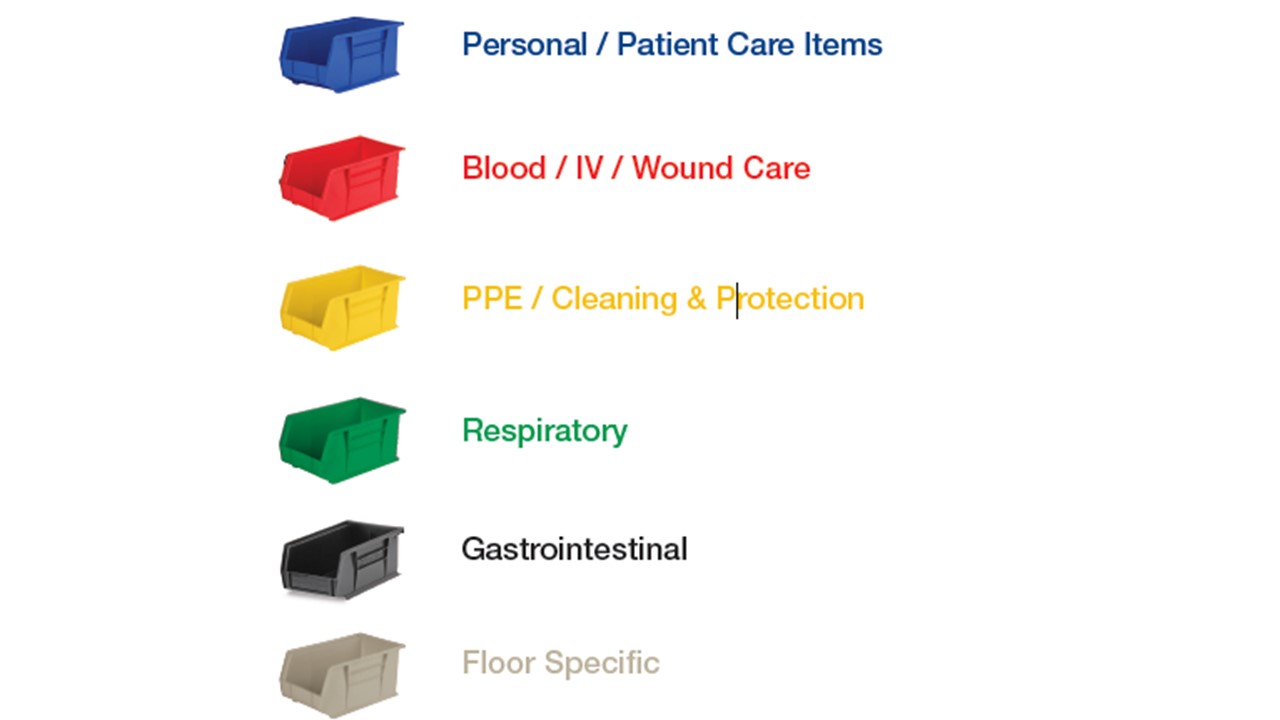

Color codes are used to apply visual management. Figure 3 shows a color code map commonly used in healthcare.

Figure 3 Health color code map

Ribbons of different colors can be used for marking, including printers that can print a warning, device label, equipment or something else used by medical professionals on these ribbons (Figure 4).

Figure 4 Marking strips

Figure 5 Marking the path of movement in health care

On the paths of the movement defined on the Spaghetti diagrams, it is necessary to notice the visual management and mark those paths, as well as everything related to the process of admission, care, and treatment of patients, from medical material, drug storage to equipment. This will ensure that there is no overlap in the paths of movement of patients with milder and more severe symptoms, but also with healthy patients. It will be enough for 2 minutes for everyone in a circle of 3600 to understand how the process takes place without anyone introducing them to it.

In Nis, 30.05.2020. Prof.dr Vojislav Stoiljković

vojislav.stoiljkovic@cimlss.rs

[1] http://www.cimlss.rs/covid-19-i-lean/

[2] https://planet-lean.com/spaghetti-chart-physical-distancing/

[3] https://www.gartner.com/en/documents/3983064/covid-19-lean-on-principles-and-values-in-tough-times

[4] https://www.biz-pi.com/applying-lean-methods-to-mitigate-covid-19-at-work/

[5] https://www.industryweek.com/operations/continuous-improvement/article/21126118/how-lean-can-help-in-a-crisis

[6] https://www.lean.org/LeanPost/Posting.cfm?LeanPostId=1141

[7] https://planet-lean.com/lean-healthcare-covid-19/

[8] Vojislav Stoiljković, Lean in Healthcare, Lambert, 2018.

[9] Vojislav Stoiljković, Lean u zdravstvu, Despot book, 2013; Vojislav Stoiljkovic, Lean in Healthcare, Lambert, 2018